All About Technical Fabrics

Today we’re diving deeper into technical fabrics! ReFasten, a shop offering technical fabrics, notions, and patterns for home sewists, kindly sent a variety of fabric samples that we’re going to take a look at. If you haven’t already, you can check out my other blog post with ReFasten detailing the color block tote I made with some of their fabrics and notions.

Sewing basket bags and tool rolls for my husband’s cycling shop has given me some experience with technical fabrics and supplies, but as a sewist of apparel primarily, many of the fabrics available for making one’s own gear are pretty new to me. The various acronyms and numbering can be confusing, and when shopping online it can be hard to imagine what to make with these fabrics if you haven’t felt them in person.

I’ve summarized a variety of the fabrics available at ReFasten so you can hopefully get an idea of what they might feel like and how they can be used by the home sewist. And because several of these fabrics are branded, its easy to search their names and find examples of projects other people have made with them (Reddit yielded a lot of results). Samples can also be ordered for most of the fabrics which is a great way to preview materials you might be interested in.

Before we get into it, a little disclaimer: I am not a chemist or a textile expert and the information in this blog post is meant to be introductory. Many of the technical fabrics we utilize for safety and comfort are only possible because of synthetic materials, however these impact the environment in varying degrees. As I researched various fabrics for this blog post it was encouraging to see that many of the leading technical fabrics are created with greater attention to their environmental impact and decreasing their negative effects on the planet. While it can be hard to avoid all synthetic materials in our current world, we can reduce harm by purchasing materials and items that are kinder to the planet and utilizing those items fully, repairing and recycling when we can.

Lets dive in!

First are the two fabrics I used for my color block Kaland Weekender Tote followed by a sampling of other offerings at ReFasten.

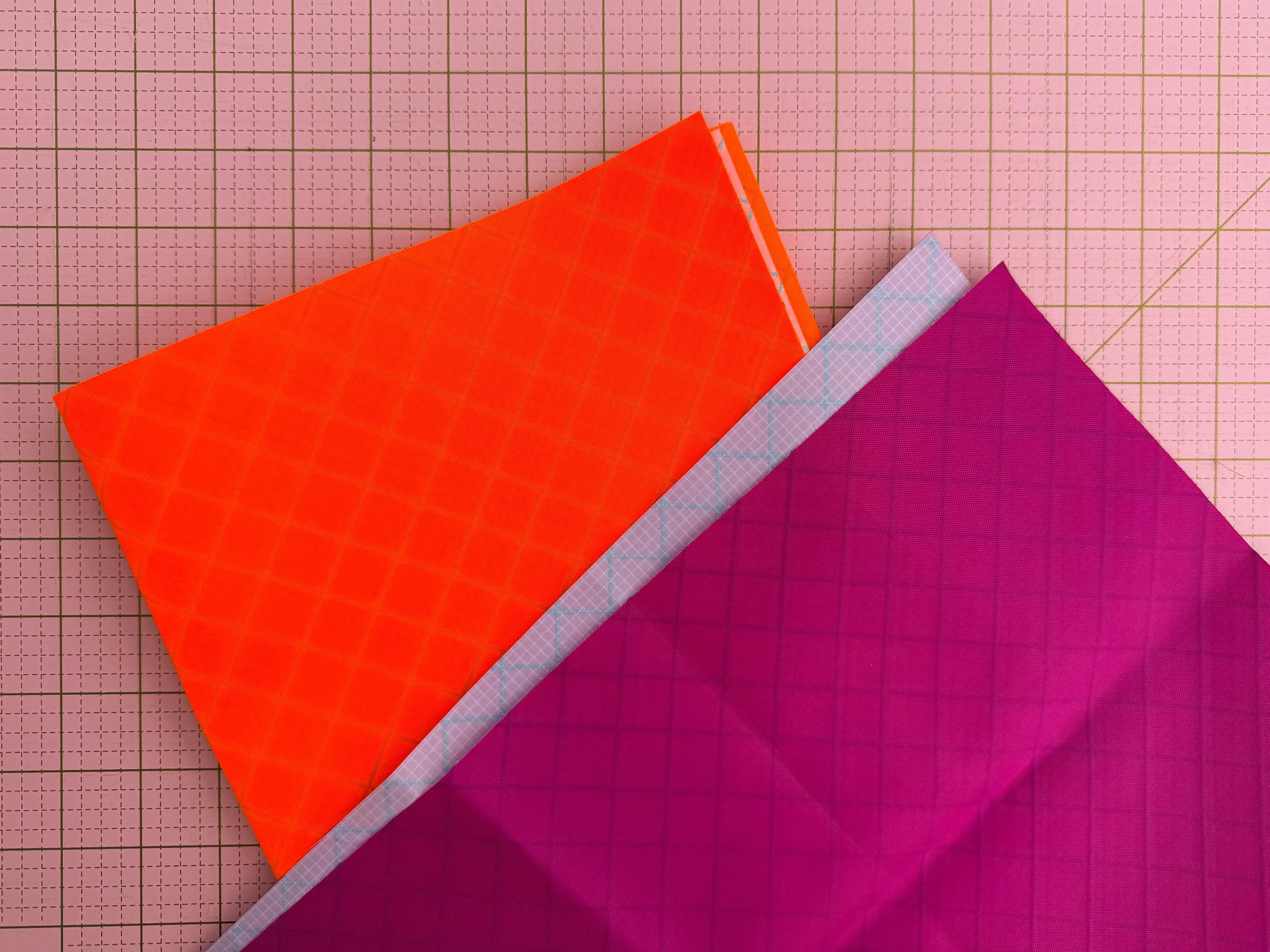

Ecopak™ EPX200

This is one fun fabric to work with! Ecopak™ EPX200 is made from recycled polyester and features a 45 degree blue cross ply and a ripstop backing. Its super strong, water resistant, and comes in lots of colors from earthy neutrals to vibrant neons. Its comes in at 6.4oz/yd making it a pretty all-purpose, mid-weight fabric. This fabric is good for all the bags—durable cycling bags, outdoor totes perfect for camping or beach days, roll top bags, pouches, pencil cases, belt bags…you name it, you can probably make it with Ecopak™ EPX200. Its also a great option for repairing worn gear. And while some technical fabrics can be challenging to work with like slippery nylons, this fabric is smooth with a stiff drape, making it easy to work with if you’re dipping your toes into technical sewing.

Tip: if you’re looking for something with a bit more heft, try the Ecopak™ EPX400. All the features of Ecopak™ EPX200 but a little heavier at 8.95oz/yd.

UltraGrid™

UltraGrid™ is a lightweight woven fabric with a ripstop weave and a PU backing, making it tear resistant and waterproof. The ripstop weave strengthens the fabric and functions as a design element as well. While very smooth, this fabric has a stiff drape and does not shift when sewing. At 3.9oz/yd this fabric is lightweight enough to be used as a lining like I’ve done with my bag, but it can also be used as the outer fabric in lightweight bags and pouches. Its particularly popular for cycling gear like saddle bags, handlebar bags, and frame bags.

Tip: thanks to that reinforcing ripstop weave, this fabric can be a bit tricky to cut. Make sure you’ve got a sharp pair of scissors or a fresh rotary blade for cutting.

Waxed Canvas Army Duck

Truly one of my fave fabrics, Waxed Canvas Army Duck is a joy to work with. This 10oz/yd canvas is a plain weave cotton with a wax coating, offering water and abrasion resistance in a more natural/eco-friendly product. It’s also a bit more breathable than most synthetic water resistant materials, making it a good choice for apparel sewing. The feel of the fabric at the machine might be new if you haven’t used it before, but it's a very user friendly material. Many enjoy the way waxed canvas patinas with use (similar to the way blue jeans custom fade to the wearer), and waxed canvas can also be recoated with wax to restore its water resistance. I’ve used waxed canvas to make tool rolls, basket bags, and totes. It also makes great accessories like wallets, hats (I’d use a lining to keep wax off your hair), and even work aprons. Lastly, waxed canvas can be used for unique outerwear—think chore coats or anoraks. The sky’s the limit, really! Waxed canvas is sturdy but pliable and sometimes has a brushed feel.

Bonus: when sewing with waxed canvas irons are a big no-no (use your fingers to press seams instead), making it perfect for summer sewing. Keep cool and sew waxed canvas!

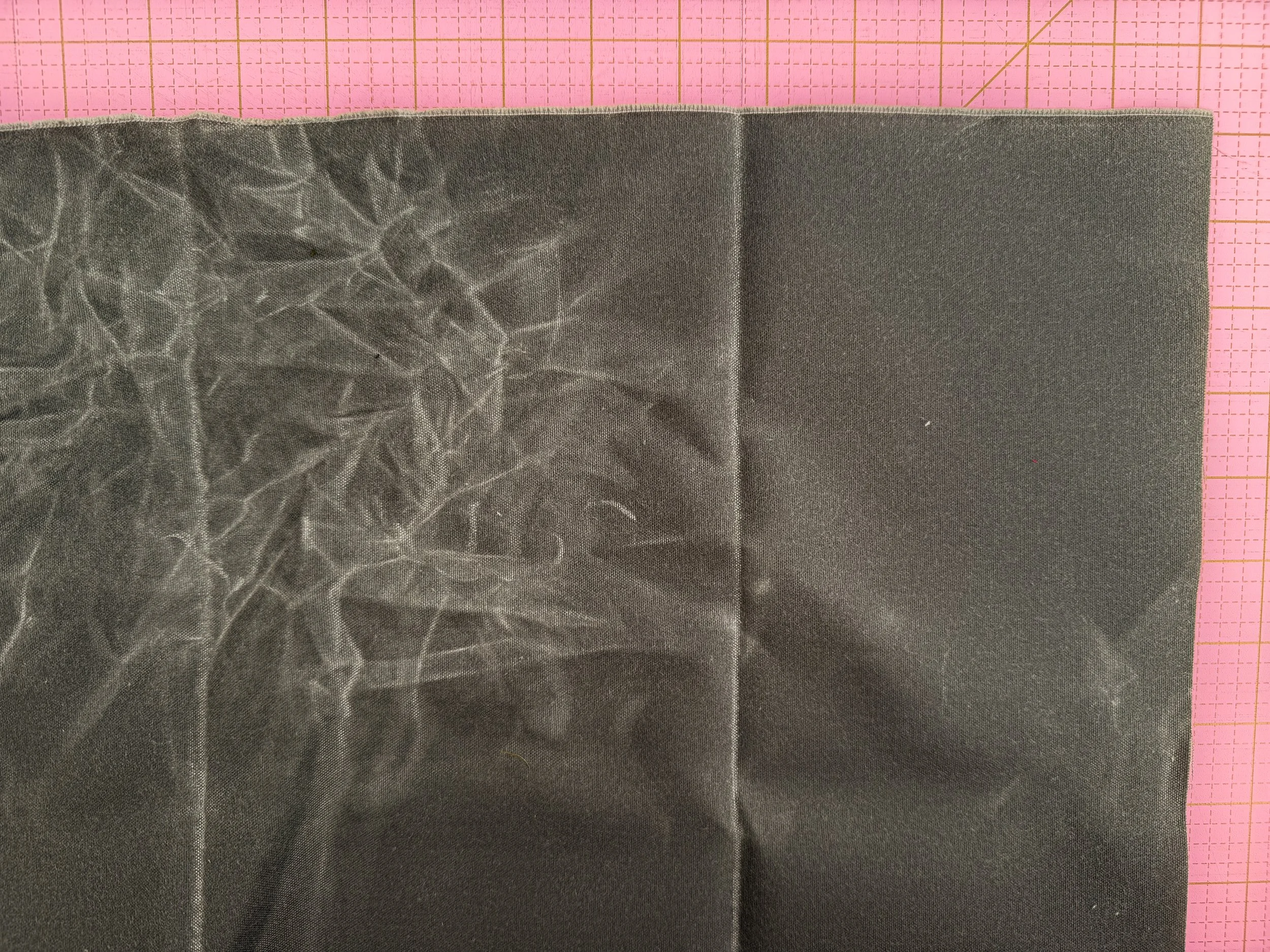

Original Waxed Canvas

Example of patina on the left side.

This is a premium alternative to the Waxed Canvas Army Duck. Original Waxed Canvas has all of the features of typical waxed canvas but with a bit smoother hand and is finished in the USA. Even though it’s softer to the touch, the weight is nearly identical at 10.1oz/yd, and still has all of the strength and water resistant benefits of the Waxed Canvas Army Duck.

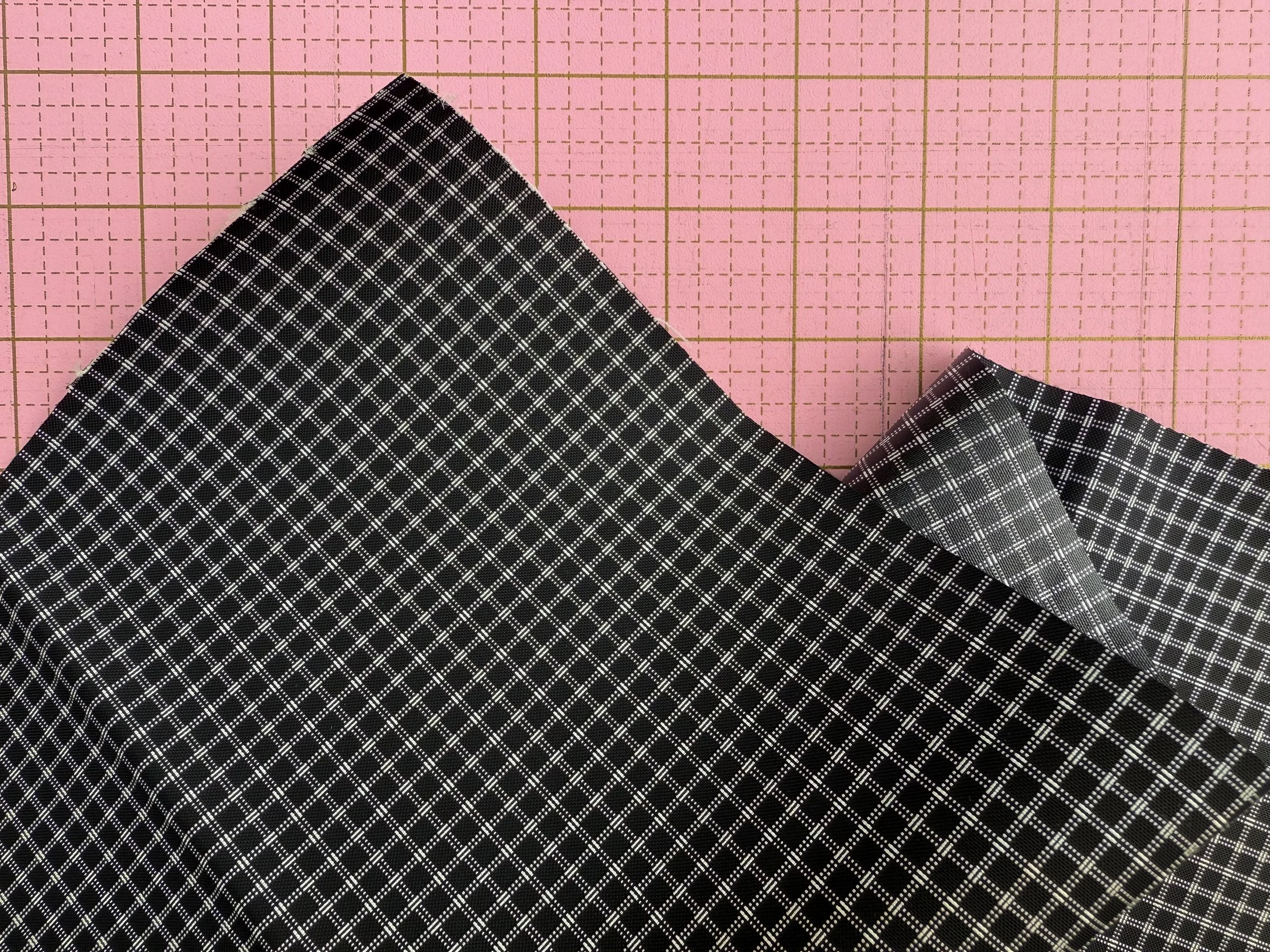

Cordura® re/cor™ 1200D

A touch lighter than the waxed canvas at 9.2oz/yd, Cordura® re/cor™ 1200D is one strong fabric for when you need to make some tough stuff. Its a plain weave fabric made with recycled polyester (sourced from bottle and packaging) intended for workwear and outdoor gear that’s meant to last. Cordura® re/cor™ can be used for day packs, virtually any kind of bag, and workwear like jackets, pants, and overalls. Its even used in shoes and on high wear areas of apparel like motorcycle jackets! Needless to say, this fabric is quite strong and tear resistant. It has a bit of texture and stuff drape, and doesn’t seem to hold on to wrinkles when scrunched. It comes in a variety of colors including neon pink, which I am just dying to get my hands on!

Tip: Want the strength and longevity of Cordura® re/cor™ 1200D in a lighter fabric? Try the Cordura® re/cor™ 600D.

RBC200

This fabric is a lightweight, plain weave recycled polyester with two different technical coatings for increased durability and water resistance. One side of RBC200 has a CO DWR* coating, a plant based coating that increases the surface tension of the fabric so water beads up and rolls off, while still allowing air to pass through. This type of coating has a smaller environmental footprint and is easier to recycle or repurpose compared to older water repellant coatings. Next, the inside of the fabric has a PU (polyurethane) coating, which serves multiple functions in technical fabric. It is also water resistant and breathable, and also increases the tensile strength of the fabric. It’s preferred over PVC as a more eco friendly option. Despite these double coatings, this fabric is only 2.95oz/yd, making it suitable for projects where reduced weight is important. It’s smooth with moderate drape, but is nowhere near as slippery as say, a nylon lining fabric one might use on a jacket. This fabric would work well for stuff sacks, pouches, packing cube-type bags, bag linings, and gear repair as well.

* “DWR” stands for Durable Water Repellent. “CO” indicates that it does not contain perfluorinated chemicals.

RBC200 RS

This fabric is a lightweight recycled polyester fabric with an added ripstop weave (as opposed to the RBC200 which is a plain weave with no ripstop). RBC200 RS features the same double coating as the RBC200 with a slightly heavier hand, weight 3.45oz/yd. The ripstop weave adds an extra layer of strength to this already abrasion and water resistant fabric. Like the RBC200 this fabric would be a great choice for things like stuff sacks, pouches, and bag linings, as well as gear bags, bike bags, and even rain covers for packs, bike saddles, etc.

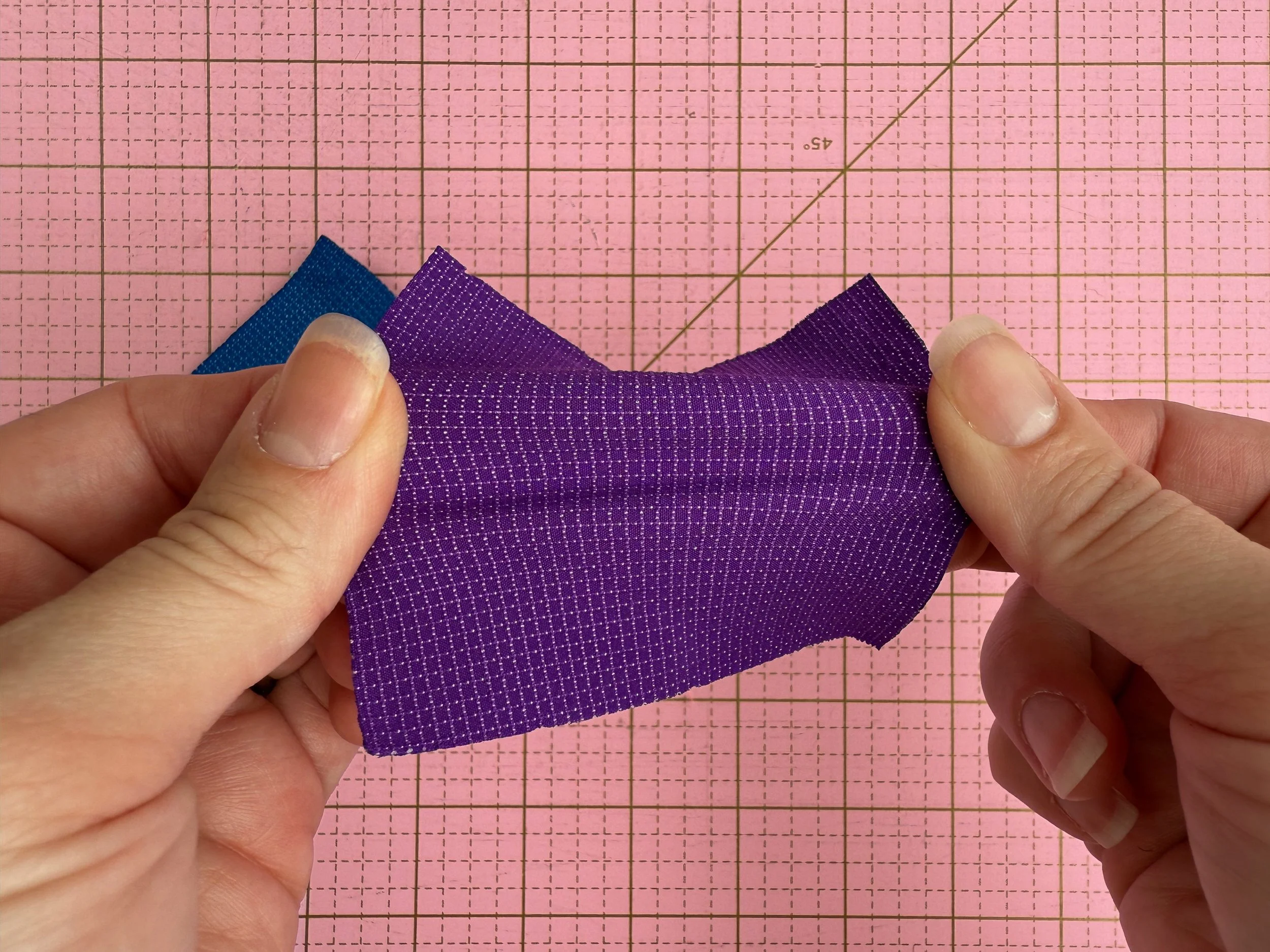

UltraStretch™

A new-to-me fabric, UltraStretch™ is essentially a stretch ripstop. Its pretty wild to play with it, to be honest! Its strong and tear resistant and yet delightfully stretchy with excellent recovery. At 5.5oz/yd its a light to mid-weight fabric made from nylon and lycra with a CO DWR coating, lending some water resistance as well. The ripstop weave results in a slight texture but the fabric is still smooth to the touch. While it can be used for whole bags, I think it would be an exceptional choice for areas that are put under tension or might need to be snug yet flexible, like bag gussets or water bottle pockets. It might also work well in warm weather apparel when you again need strength and flexibility—think gussets in pants.

Hopefully this overview has been a helpful introduction to technical fabrics and the ways they can be used by the home sewist. The folks at ReFasten are a great resource if you’re looking for some guidance on which fabrics would work well for your project as well.

Thanks again to ReFasten for providing these fun fabrics to explore!